But that is, indeed what the mission is: by 2021, NASA plans to have harnessed an asteroid for not only exploration, but also as a way of planting them in the moon's gravitational orbit, thereby giving future space missions (to Mars, finger crossed) a natural satellite base.

It's an incredibly extensive, yet resourceful, idea. Working within the constraints of a criminally small budget, NASA figured out a way to create a station stop on the way to Mars that's cheap to maintain and also may contain resources and raw material in itself that would serve a myriad of purposes, from gold and rare metals to ice water. Oh yeah, and if it proves successful, it will serve as a blueprint for capturing an asteroid that could threaten to extinguish all life on Earth. What is that, three birds with one stone, right?

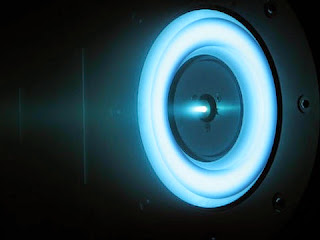

To me, though (or should I say to my employers, because this is a blog about manufacturing) the real interesting benefit to the mission has nothing to do with the end results of Mars or the Moon, but with how the technology will be used. And that involves xenon-fueled ion thrusters. Yep. Ion rockets. Why is this a big deal and what does it have to do with manufacturing? Here's why:

It's no secret the future of space and any industry having to do with it will include private investment and capability. NASA has all but given the Moon to private firms who want to land there, and they're more than likely going to need private funding for steps in the engineering process. This includes the ion-powered thrusters that will be crucial to the feat of getting a spacecraft mobile enough to catch a floating rock.

This specific innovation, in my opinion, could revolutionize 21st century space travel by permanently removing its dependence on gravitational orbit for transit. Think about the possibilities of exploration that open up when shuttles can travel away from Earth for short periods of time. Moreover, while it is true that ion energy works best in an environment like space, without other ionized particles, that doesn't leave out room to discover other applications for it here on the ground. The concept of using ionized energy itself is barely a century old, who knows what else we can learn from it?

Donal Thoms-Cappello is a freelance writer for Rotor Clip Company.